If you are an OEM or a regional distributor you are held responsible for your medical device by the local authorities. Depending on your sales markets you must get approval for your medical device and therefor need to fulfill requirements described in NMPA (CFDA), FDA, MDR, IVDR*, or others.

On a high level the requirements are set for product design phase; supply chain; production and product life cycle management – literally for all phases a new product will go through.

Consequently, every process in your organization needs to be approved and ready for audit at any time.

On the other hand, medical products see price pressure, innovation cycles and a growing complexity. Later one is especially true for products combining different technologies into a complete solution e.g., robotic navigation, diagnostic assistance, automated analytics. Even large players in those product segments

Changing perspective: When you are a supplier, ISO 13485 provides your organizations with guidance for quality of your components and services, with the goal of closing the gap to the quality level of your medical OEM customer. That needs to be seen as a real added value.

Relationship to ISO 9001

Although ISO 13485 is a standalone standard, it is based on ISO 9001:2008, which has been replaced by ISO 9001:2015. ISO 13485 has an additional set of requirements specific to the medical device industry, and it discards some of the requirements of the new ISO 9001. Therefore, compliance with ISO 13485 does not imply compliance with ISO 9001, and any organization that aims to be compliant with both standards has to implement all applicable requirements of both ISO 9001 and ISO 13485.

* NMPA – National Medical Product Administration; FDA – Food and Drug Administration; MDR – Medical Device Regulation (EU); IVDR - In Vitro Diagnostic Medical Devices Regulation (EU)

A certified supplier makes your life easier

To demonstrate compliance with the standard and legal requirements, each of your medical devices needs to have a medical device file. The content of the file must include, at a minimum, a general description of the file; specifications for the product; procedures for manufacturing, storage, packaging, handling, and distribution; procedures for monitoring and measuring; requirements for installation; and procedures for servicing. Procedures need to be documented, issues need to get a root cause analysis and performance of procedures need to show evidence.

Sametime, your supply chain is optimized on costs and time. Which means that major parts and components of your medical device will be manufactured by third party suppliers. The supplier is an attractive alternative to inhouse production as he consolidates demand from multiple OEMs – often also from different industries - to reach a higher level on the cost curve. Most likely the supplier has a QMS according to ISO 9001. Do you see the gap?

A supplier certified according to ISO 13485 provides the best way to apply those extra requirements along your supply chain:

Product Design | R&D | Production | Purchasing |

discuss the technical requirements based on OEM application | audits, hand-out documentation, requirements management, validation, complaints handling | first article inspection, tracing of components, no-change-agreement, version control | subcontractor management, last-time-buy terms |

Table 1 “ISO 13485 Requirements for Suppliers”

In a nutshell, an OEM has has less effort for documentation and processes to reach compliance and has less risk and costs in production and supply chain when choosing a supplier holding ISO 13485.

Most important, communicate to your supplier already in an early phase. From experience this phase takes 4 to 8 weeks. Experts in Quality Management and Supply Chain Management will meet their peers and discuss all requirements of the ISO 13485. Some of the requirements the supplier can easily switch “on” others are more like services which need to be defined based on OEMs boundary conditions.

Main output is a Quality Assurance Agreement (QAA) which defines all relevant aspects according to ISO 13485 for your specific product/ situation. The QAA will be signed by OEM and Supplier and is subject to the future business.

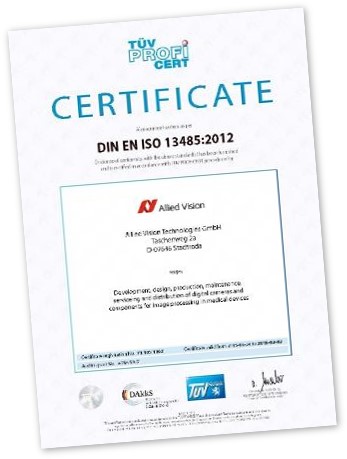

All Allied Vision R&D and manufacturing sites worldwide are certified according to the quality management standard for medical equipment DIN EN ISO 13485:2016, including yearly audits by TÜV on site. This extra effort is well spent as the medical OEM literally defines the interface to his supplier – reliable, transparent, and according to his own requirements.